Week 11 - Manufacturing Aspects of Design

Read this entire document before starting the assignments.

-

Objectives

-

Reading assignment

-

Properties and Processes in Design

-

Discussion questions

-

Lecture Topics

-

Week 11 assignments: CS 1st

Draft CS Contact Summary

-

Reference Material

Objectives:

|

Determine how specifications determine

process options |

|

Review case study of a new type of Ice Axe |

|

Review contacts and case study performance indices |

|

Study how to use longer case studies into student case studies |

This week we will have the midterm on Monday, and then discuss the Ice

Ax case study. Beginning this week we will focus on Case Study related

topics. In addition, as time permits, some optimization and statistical

topics will be added as these are increasingly considered necessary tools

for an engineer.

Reading Assignment:

|

ASM pages 669 - 686, 716 - 723,

762 - 772, and 820 - 827 |

Properties and Processes in Design:

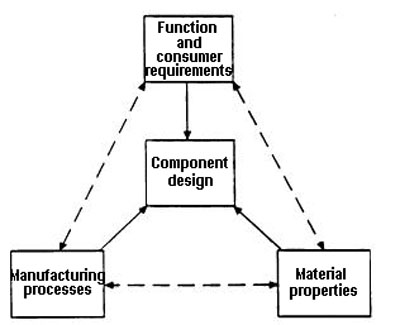

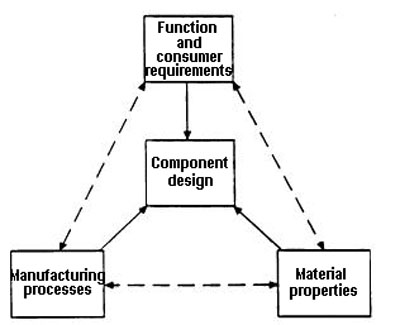

This figure, and the four following it, is taken from The ASM handbook

text , 509 , M.Farag," Properties needed for Static Structures". It describes

the linking of processing and properties in a design. This linking should

at least be acknowledged in a case study.

Fig. 1. Factors that should included in a component design.

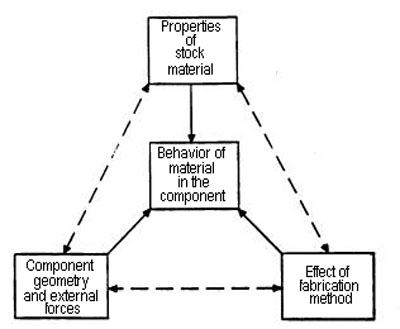

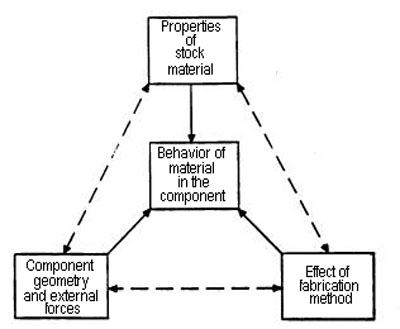

Fig. 2 Factors that should be in considered in anticipating the behavior

of material in the component.

This is taken from Farag, opcit, and relates model, from which the performance

indices are taken, to materials properties , geometry and fabrication.

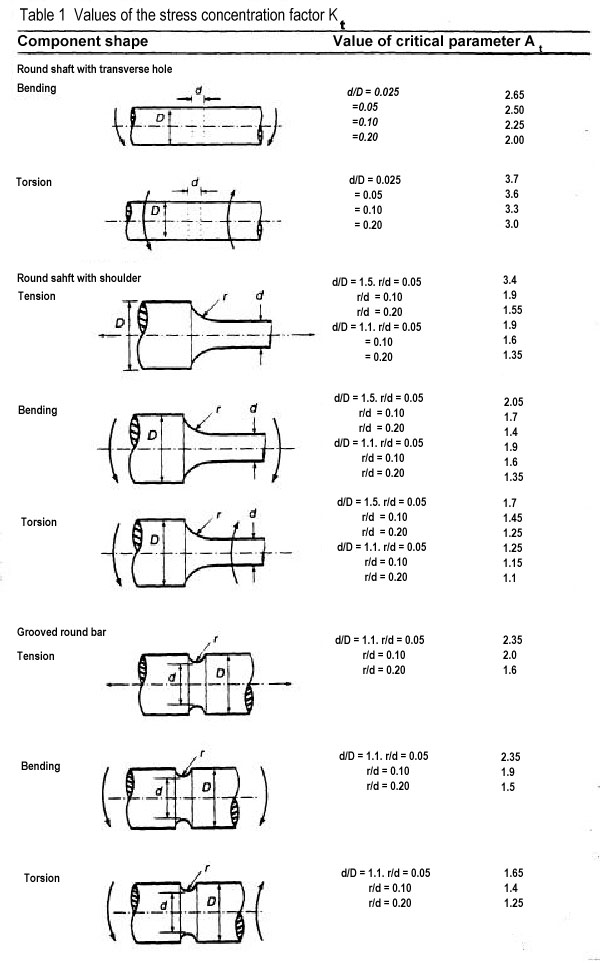

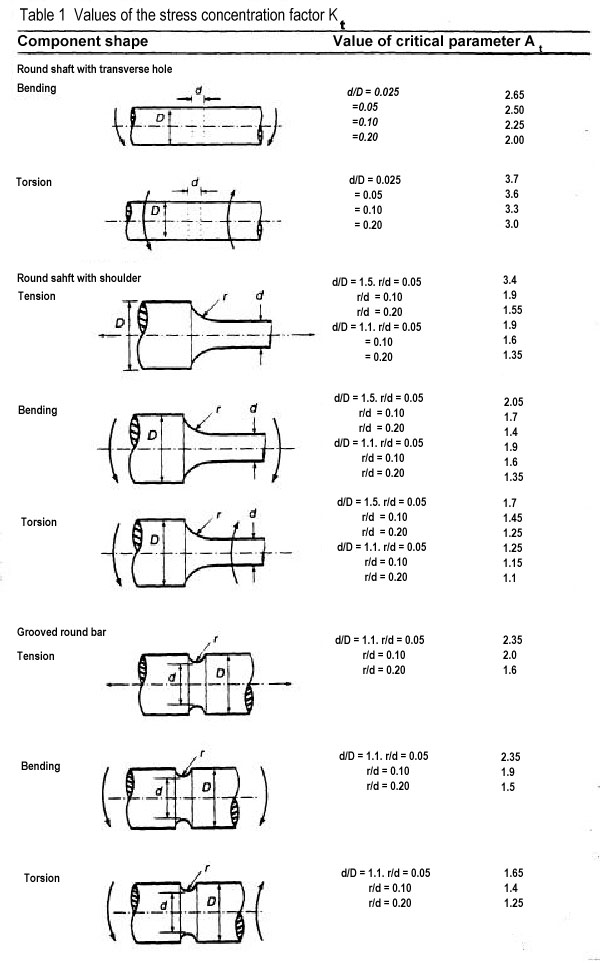

This figure is Table one from Farag , op cit page

510, and shows how component shape will reduce safety margins throughout

the inclusion of stress concentration points.

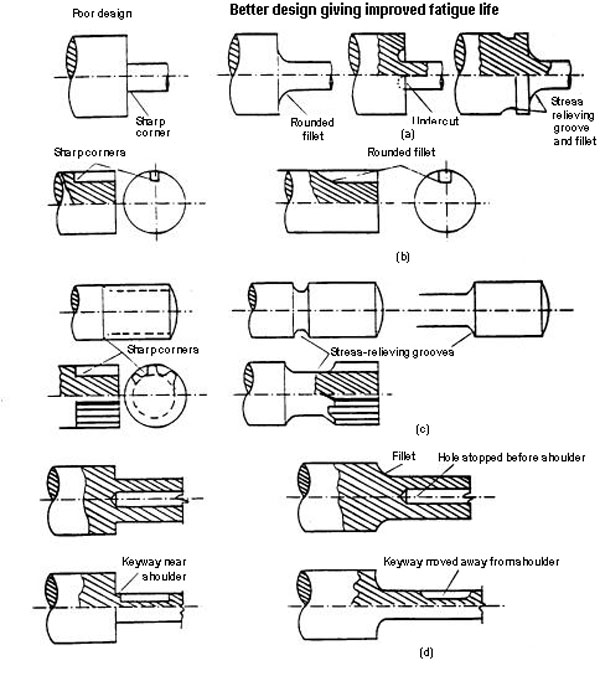

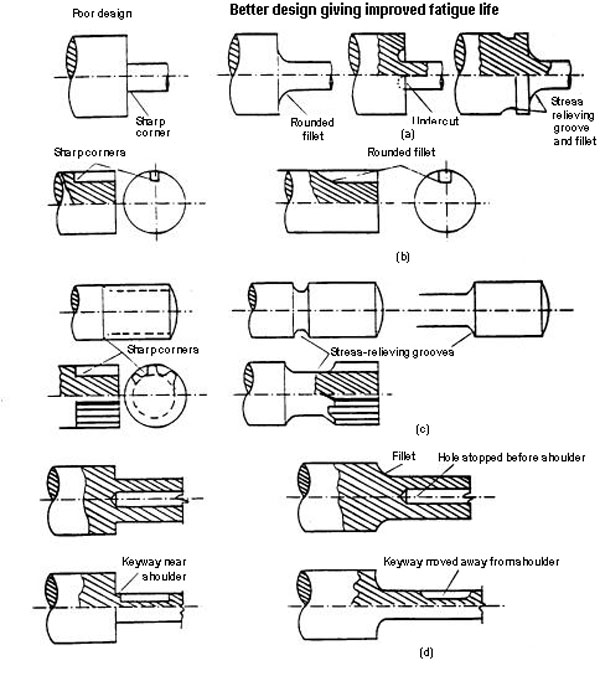

This figure , Farag op cit page 511 shows poor and

good design practice for mechanical components.

Fig. 3 Design guide lines for reducing the deleterious effects of stress

concentration. See text for discussion.

Source: Ref. 1

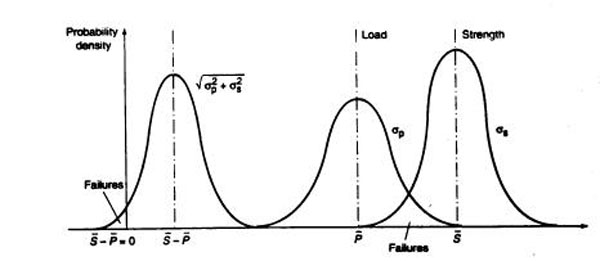

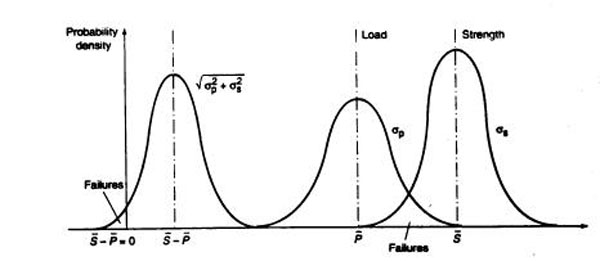

This figure, opcit Farag, page 511 shows how variations

in the load on and the strength in a material combine to result in

a finite failure probability even when the nominal load is a safety factor

less than the nominal strength of the component.

Fig. 4 Effect of variations in load and strength on the failure of

components.

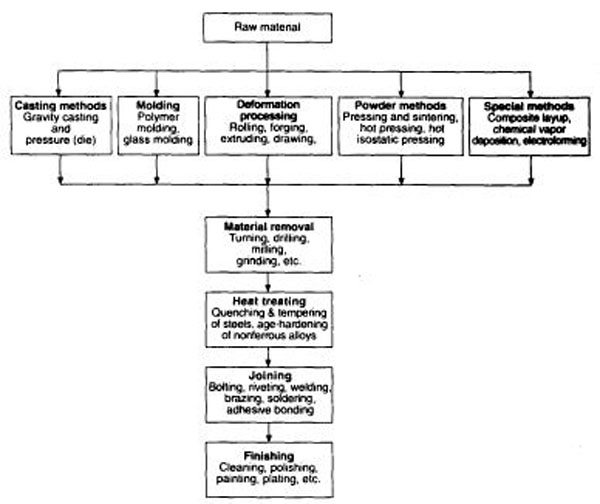

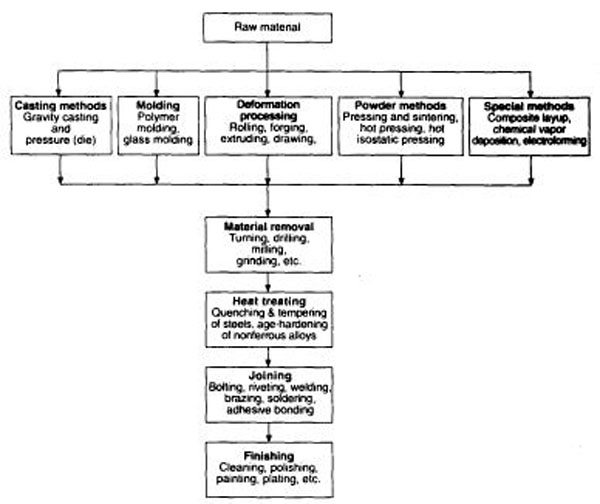

This table , and the one below it , are taken from

the ASM textbook , G.Dieter, Overview of Materials Selection Process, P247.

The top figure describes the nine classes of manufacturing process. However,

the micro fabrication processes that are beginning to pervade much high

technology would probably want their own category rather than being lumped

in with "special methods".

Fig. 4 The nine classes of manufacturing processes. The first

row contains the primary forming (shaping) processes. The processes in

the vertical column below are the secondary forming and finishing. Source:

Ref 21

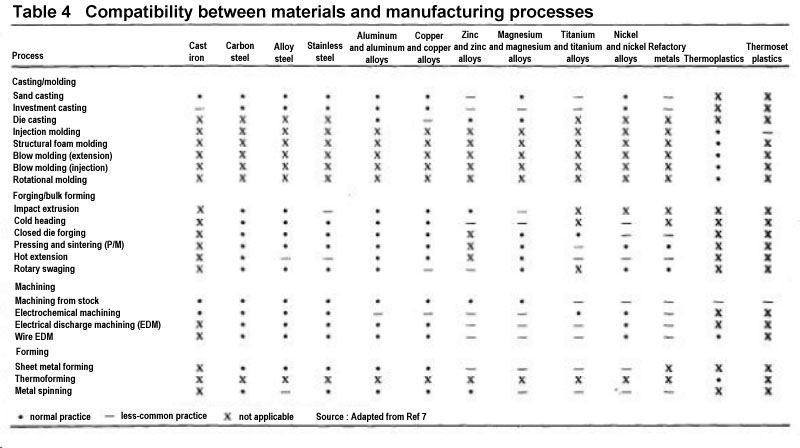

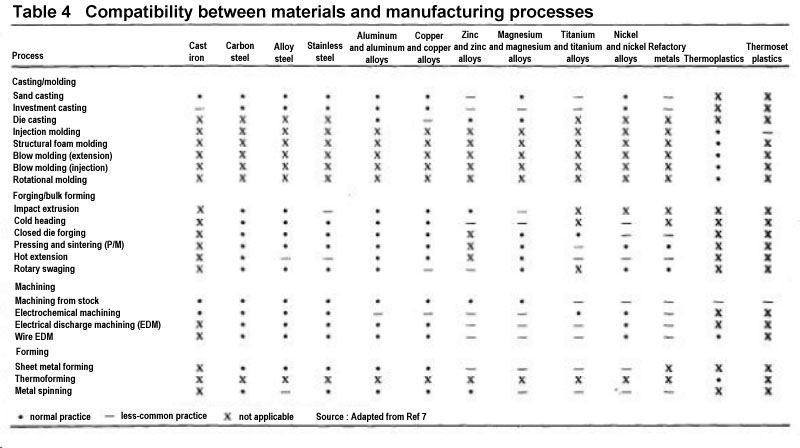

This is an important figure, again taken from Dieter

, ibid., page 247. It is , in essence, a sanity check wherein the selection

of a material and processing technique can be checked for compatibility.

Alternatively, if a company has a particular process in house, that will

tend to limit the materials that can be chosen for a given application.

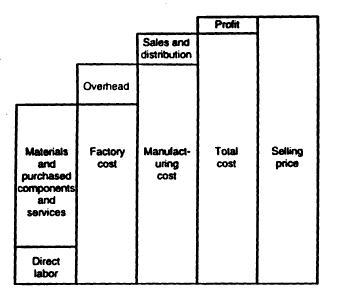

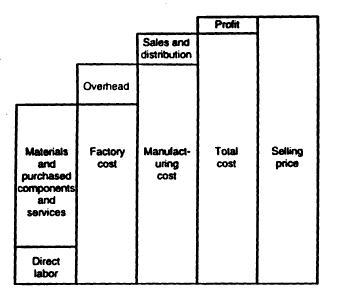

Fig. 5 Buildup of cost elements to establish selling price.

This figure is Dieter opcit fig2. page 300. It shows how price is developed

from cost by adding factors such as production overhead (atop of factory

cost) and sales and distribution costs and profit. In many cases the final

cost is a factor of 3-5 times the labor and materials costs. Not shown

is the financial component involving write-off of research and development

, taxes, and the cost of capital. In addition , there are inventory costs

and various aftermarket costs involving customer support and product servicing.

Discussion Questions:

|

How is manufacturing different

than processing? |

|

How are engineering and end user requirements integrated into new product

design? |

|

How are Ashby material/process selection techniques integrated with

other techniques in student case studies? |

Lecture Topics:

|

Monday |

Midterm Exam 1 hr, closed book |

|

Wednesday |

Review midterm, manufacturing and processing compared |

|

Friday |

Review Ice Ax case study, update student case study progress, preview

chemical process industry case study |

Week 11 Assignments:

First Draft Case Study (Due 11/25/98)

Subject: Week

11 - Case Study 1st draft

The case study first draft is due just before Thanksgiving, so

it is time to start integrating the parts you have previously prepared.

Presentation of Case Study: Summaries of discussions

with external sources (Class period 11/13/98)

During this Friday's class one or two of you will

discuss the interactions with external sources you have had in the course

of preparing your case study.

Reference Material:

This is a site which reviews materials selection for the NASA space

shuttle

http://www.ksc.nasa.gov/shuttle/technology/sts-newsref/sts_sys.html#sts-rcc

This site is a great starting point for information on Composite

materials

http://composite.miningco.com/

Since environmental factors are key extrinsic factors in a case study

, this site provides an outstanding entree point for environmental issues.

http://www.lib.uidaho.edu:70/docs/egj07/schrode.htm

Last update 8-14-98

Last update 8-14-98