go to WEEK 8 Online Course Support

MSE 5090: Case Studies in Material Selection

Week 8 - Midterm Review

Example Problems

- Eating Utensils - Ranking

- Eating Utensils - Fracture Toughness

- Case for Notebook Computer - Shaping

- Processing Methods

- Solutions

Problem 1Eating Utensils - Ranking

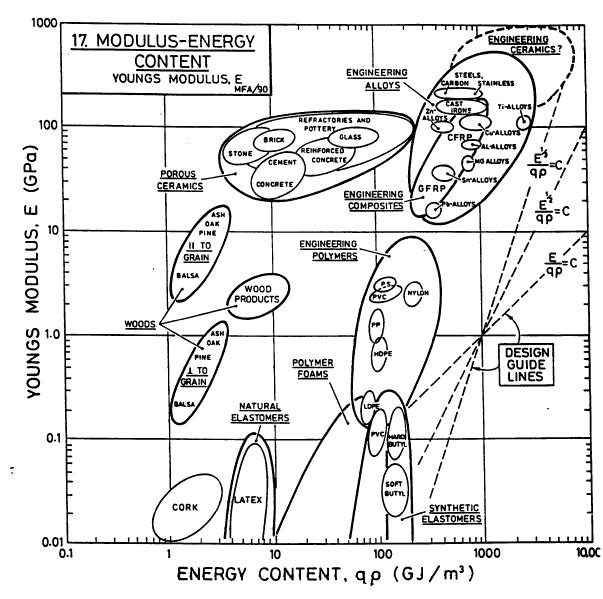

A California restaurant is going to order some eating utensils (knife, fork etc.) that are both luxurious and environmentally conscious. The shape of each (and thus the length, width and profile) are fixed, but the thickness is free: it is chosen to give enough bending stiffness to cut and impale without excessive deflection. The proprietor wishes to enhance the greenness of his image by minimizing the energy content of his eating utensils, which could be made of stainless steel, titanium alloy or even stones (natural rocks).One can model the eating implement as a beam of fixed length (l) and width (b), but with a thickness (t) which is free, loaded in bending. The objective function is the energy content (Q): the volume (V) times the energy content density (qr),energy content per unit volume. The limit on deflection imposes a stiffness constraint. Use this information to develop the performance index, and use it, with proper chart, to rank three material candidates.

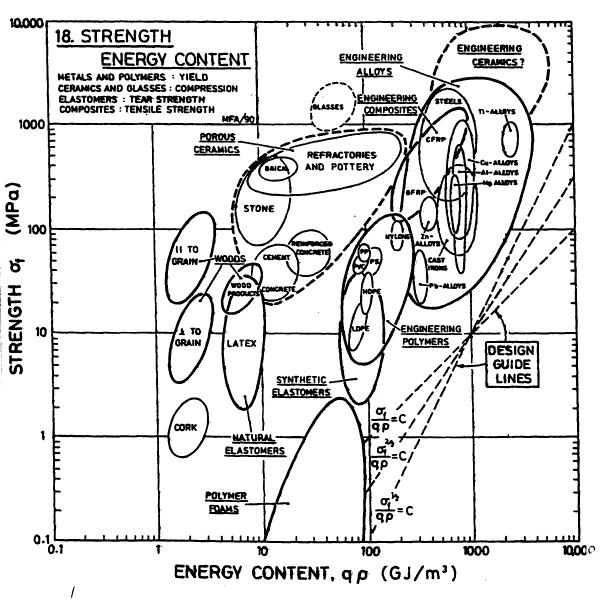

Deflection, in cutlery, is an inconvenience; failure is more serious: it causes loss of function; it might even cause hunger. Repeat the analysis, using a strength constraint. Use proper chart to decide if your initial rank of the materials is still valid.

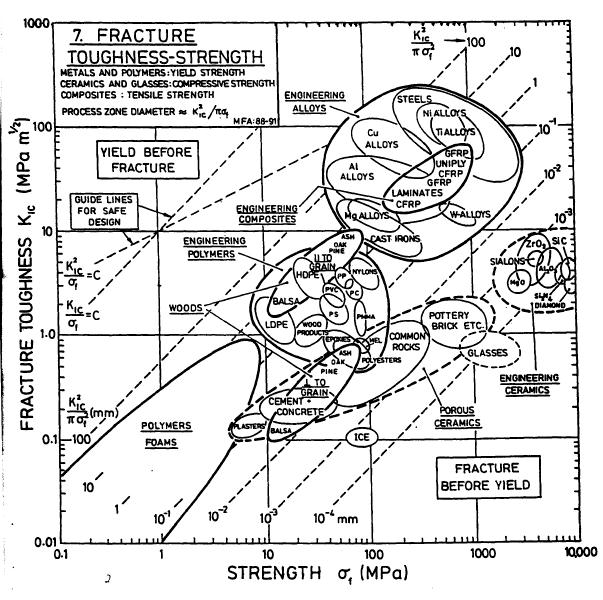

Problem 2Eating Utensils - Fracture Toughness

If fracture toughness is going to be a concern for the eating utensil manufacturers, who set up a minimum requirement of 10 Mpa m1/2, will these manufacturers agree with your preference in problem 1?

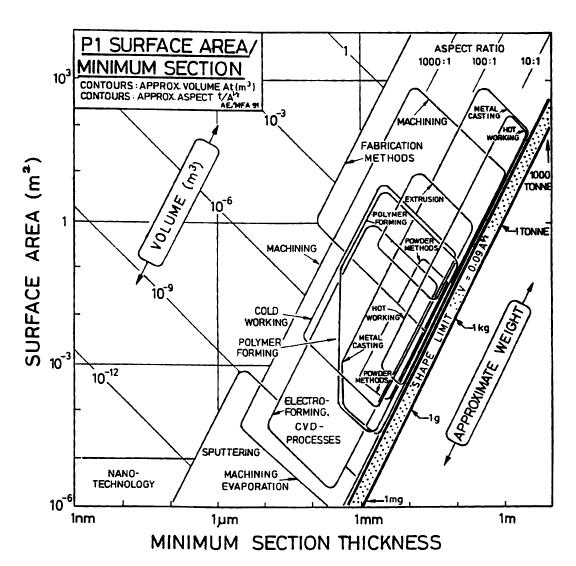

Problem 3Case for Notebook Computer - Shaping

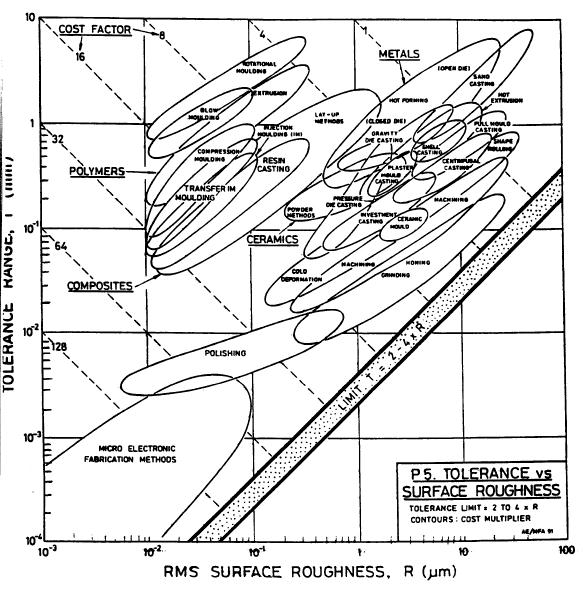

A case is required for a notebook computer. The sales department insists on an A4 footprint and a thickness no greater than that of a paperback novel. Translated into more rational units, the outer dimensions of the case are 280 x 220 x 20 mm, with a wall thickness not exceeding 2 mm. It is to be made in two pieces (a base and a lid, each about the same size) from thin aluminum sheets. The tolerance T on the larger dimensions is specified as ±0.5mm; the RMS roughness R must not exceed 0.5 m.m. Please identify the best way of shaping the case. (Show your answers on the proper charts.)

Problem 4Processing Methods

There are ten products listed bellow, please find the proper processing methods from the choices provided. (Fill the letters of processing methods into the brackets.)

Products: Processing methods: (1) Coins ( ) ( a ) Cold rolling (2) Turbine blades ( ) ( b ) Hot rolling (3) Telephone receiver ( ) ( c ) Powder metallurgy (4) Metal welded pipe ( ) ( d ) Die forging (5) Tires ( ) ( e ) Slip casting (6) Steel auto body panels ( ) ( f ) Injection molding (7) Ceramic plumbing ware ( ) ( g ) Compression molding (8) Plastic football ( ) ( h ) Extrusion (blow molding) (9) Composite gulf club ( ) ( i ) Rotational molding (10) Plastic milk bottle ( ) ( j ) Pultrusion

Last update 10-18-98